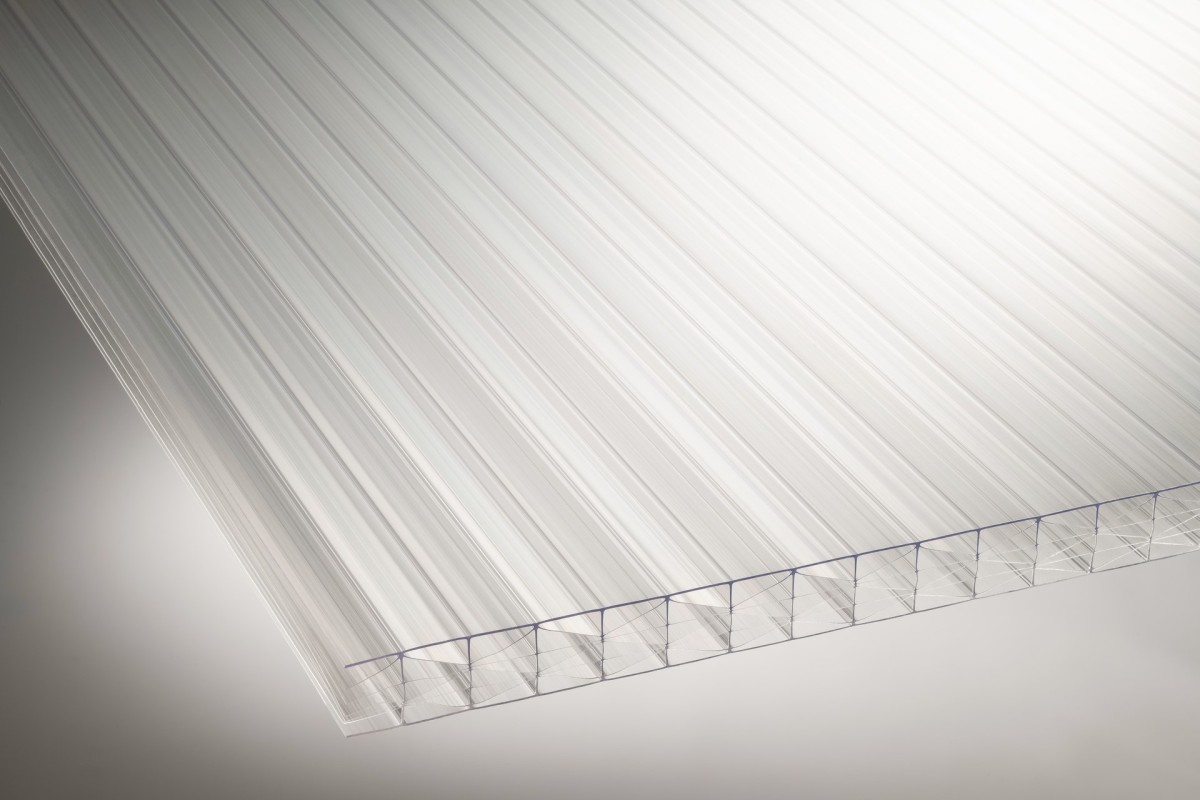

Multiwall and flat polycarbonate sheets are an important component within the doors, roof and chimney panels of aisle containment systems, vital for structuring of segregated data zones as they provide a reliable environment for maximum uptime and more cost-efficient cooling for servers.

Brett Martin is a world-leader in the manufacture of polymer-based sheets and it has developed highly sustainable options that include polycarbonate panels made from low carbon bio-circular materials which it supplies to aisle containment providers.

Produced from climate neutral bio circular attributed polycarbonate resin, the company’s Marlon BioPlus is the lowest carbon sheet option for use in any new build or upgraded data centre project.

Compared to standard polycarbonate panels, Marlon ST BioPlus provides an LCA A1-3 carbon saving of 97%, equivalent to savings of between 200 - 500 tonnes of embodied carbon in a typical new build data center, dependent on the aisle containment design.

The carbon savings are achieved by replacing fossil derived feedstocks with sustainably-sourced feedstocks in addition to savings from the use of renewable energy throughout the manufacturing process.

Brett Martin’s process is audited and certified by International Sustainability and Carbon Certification (ISCC Plus) which provides assurance to customers that the mass balanced approach to substitution with low carbon materials is followed throughout the supply chain.

Robin Black, Head of Strategic Development at Brett Martin, says: “While the use of sustainable energy in data centres is reducing the impact of operational carbon, the data centre industry is now preparing to meet the challenges of reducing embodied carbon in the building’s design, with many developers striving for net zero. Scope 3 emissions have become the most significant part of a data centre’s impact.

“Brett Martin’s low embodied carbon polycarbonate sheets provide a very significant carbon saving when compared to standard options. By adopting these new low carbon Marlon panels in data aisle containment, developers can reduce scope 3 emissions with the confidence provided by our LCA data and certified performance.

“On a large development, our Marlon BioPlus option can reduce embodied carbon by hundreds of tonnes of Co2 eq, depending on the aisle containment design and in every case the savings will make a contribution towards attainment of Net Zero. Brett Martin uses third party reviewed Life Cycle Assessment (LCA) data, calculated according to leading international standards, to calculate the carbon saving,” he continues.

“Building regulation is travelling towards a firm focus on climate action, with the next LEED update expected to be heavily weighted towards decarbonisation. Making informed decisions about the carbon footprint of both the building fabric and fitout is therefore essential in the drive to reduce environmental impact,” Robin adds.